Partners - 80/20 Inc.

Company Profile

The Industrial Erector Set

Founded by Don Wood in 1989, 80/20 is indeed “The Industrial Erector Set.” The company’s product innovations have led to tremendous growth in just over 25 years, boasting more than 400 employees and a 300,000 square-foot campus in Indiana. Their flexible product allows you to mix, match, and assemble/reassemble components to create unique custom framing solutions. The modularity of 80/20 aluminum extrusion profiles enables easy assembly and reconfiguration to meet evolving needs.

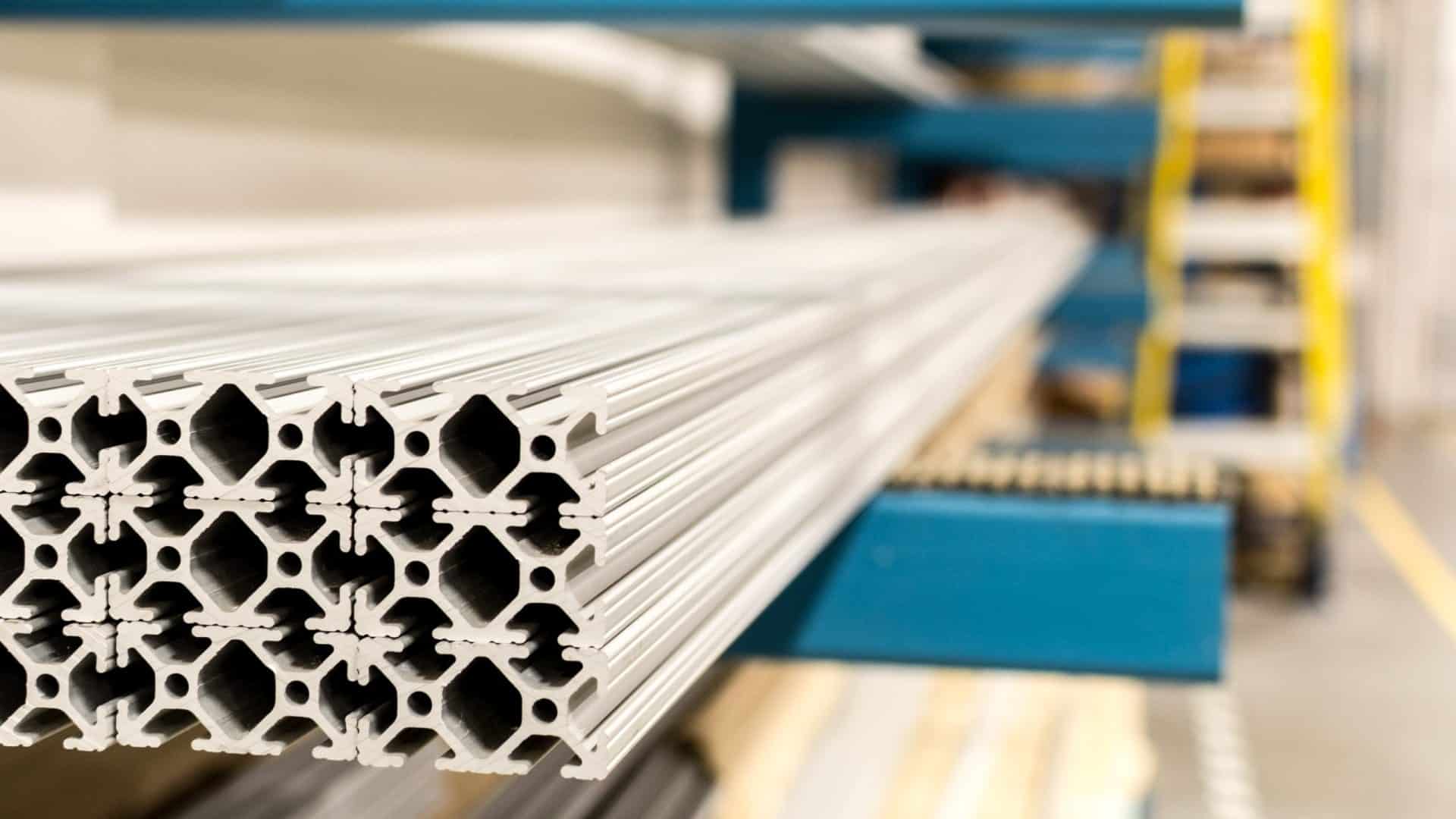

Extrusion Profiles & Fastening

80/20 offers a wide range of 80/20 aluminum extrusion profiles, including T-slot options, giving you the flexibility to tackle any project. With versatile fastening solutions and thousands of accessories, you can easily customize your build. In-house anodized and custom finishes ensure durability and a professional look.

Machine Framing, Safety & Guarding

80/20 is the perfect solution for machine framing, safety, and guarding. Flexible mounting solutions and extensive accessory options make implementing your structural framing and safety requirements simple. Develop custom designs that fit your operations while integrating your components seamlessly.

Minimize risk and meet MSHA and OSHA standards by mounting safety components directly to your frame. Reconfigure your design easily to accommodate growth or change—while reducing costs.

Product Highlights:

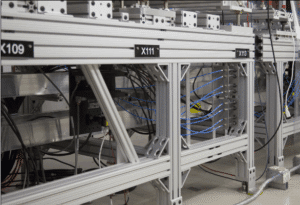

Structural Solutions to Support Data Center Services

Design for Flexibility

Data centers are the enablers of our progressively more data-hungry world. If these mission-critical spaces aren’t optimized for real-time performance, then the result is service outages, lost productivity, higher costs, and missed opportunities.

- Scale on the Fly – As operational demands change, your data center layout must keep up. Structural systems that are easy to reconfigure and repurpose allow you to design spaces and supports for designs that suit the way you want to operate today, tomorrow, and beyond.

-

Less Labor Time – Data center operators are experts at maintaining and monitoring data center systems. Let them do what they do best by using framing systems that are fast and easy to assemble and require few tools. Build framework for a partition or an aisle containment system and they should be able to do so quickly without lots of training.

More Uptime – People depend on your data center operations. Equipment damage can lead to unplanned downtime, where even short outages have lasting implications. To protect availability, framing systems must be strong, durable, and safe to use around electronic equipment.